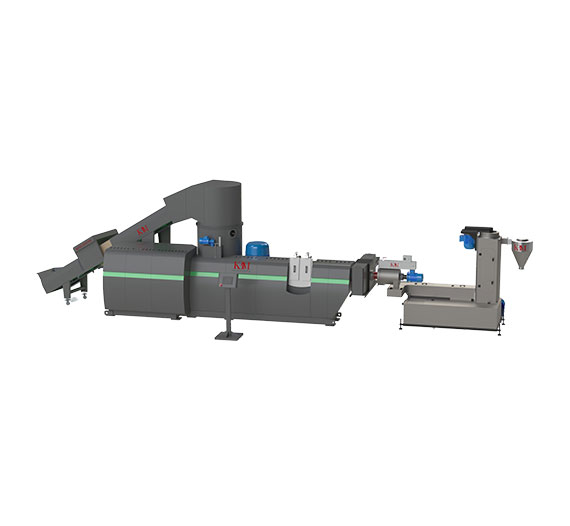

Flim Recycling – Single Stage

Industrial film waste can be best utilised and easily recycled with the smartest operation of this KBM Recycling Machine. This gives the highest value to your waste, better production and future giving Zero Wastage. Cutter Compactor helps in preheating the material, removing certain moisture before entering the Extruder, giving high performance and quality raw material. Material is first shredded with the help of the blades and compacted to give easy feed to the extruder. Pre heating of material helps in removing moisture and some ink content to high rotation in compactor vessel. Extrusion becomes Simple and Energy Efficient giving high quality pellets and output.

Applicable plastic materials

(PP Ropes, Fibers, Woven, Non-woven, PP Rafia, BOPP, CPP, HDPE, LDPE, LLDPE, PET, PA, PC, EPE, EPS, Regrind Plastics etc.)

WOVENS & NON-WOVENS

FIBERS & NETS

PP ROPES

PP/PE/PET LAMINATED FILMS

PE, PP ,BOPP ,POLYESTER FILMS

| MODEL NUMBER | OUTPUT |

|---|---|

| 65mm Cutter Compactor | 70 to 80 kg/hr |

| 75mm Cutter Compactor | 100 to 150kg/hr |

| 85mm Cutter Compactor | 180 to 200kg/hr |

| 105mm Cutter Compactor | 250 to 300 kg/hr |

| 120mm Cutter Compactor | 400 to 500kg/hr |

| 150mm Cutter Compactor | 500 to 700kg/hr |

| 180mm Cutter Compactor | 800 to 1000kg/hr |

Note - Output is depend upon the material, its contamination, MFI & thickness.