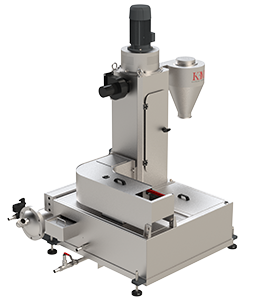

Pelletizer

For polymers that has low viscosity melts, making cylindrical pellets.

| MODEL NUMBER | OUTPUT |

|---|---|

| KBM P50 Pelletizer | Approx. 20 kg |

| KBM P100 Pelletizer | Approx. 150 kg |

| KBM PCC150 Pelletizer | Approx. 300 kg |

| KBM PCC230 Pelletizer | Approx. 500-700 kg |

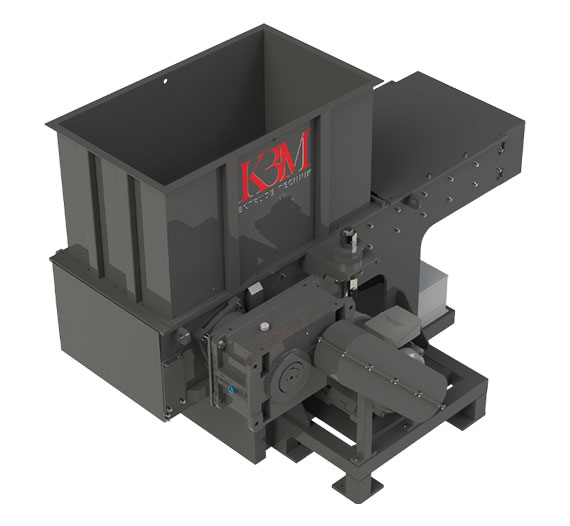

Shredder

As a Next-Gen Giant recycling machine manufacturer, KBM specializes in high-capacity machinery for efficient processing. Our solutions encompass heavy-duty shredders, granulators, and automated systems tailored to handle up to 1500 kg/hr. We prioritize sustainability, offering eco-friendly practices and expert consultations for optimal production.

| Sr. No. | Model | Output |

|---|---|---|

| 1 | EcoShred Pro 3080 | 300-400kgs |

| 2 | GreenTech ShredMaster 4080 | 400-450kgs |

| 3 | EnviroSlice Elite 40100 | 550-600kgs |

| 4 | SustainaShred Xpress 40120 | Upto 1000kgs |

| 5 | EcoCycle ShredTech 40150 | Upto 1500kgs |

| 6 | RenewaShred Precision 3080 | 800kgs |

| 7 | VitalCycle ShredMax 40100 | 1200kgs |

| 8 | EarthGuard TurboShred 40120 | 1500kgs |

| 9 | EarthGuard TurboShred PRO 40120 | 1800kgs |

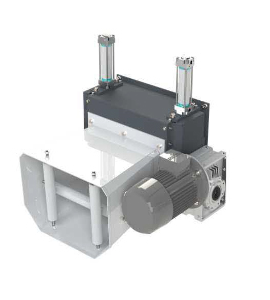

Dewatering Die Face Cutter

Cutting Hot Melt plastic into round pellets on the Face of the Die.

Dosing

For Addng Master Batches, additives Proportionately during Recycling process.

Air Knife

High Pressure Air Blowing and suction for Dry Pellets.

Screen Changer

Filter with dual Filter System for nonstop operation and reduces machine down time.

Water Tank

Water cooling the strands for cylindrical pellet cutting.

Roll Feed

To feed scrap rolls into cutter compactor vessel.

Belt Conveyor

To convey the scrap material into cutter compactor vessel.

Air Feed

To feed scrap rolls into cutter compactor vessel through blower.

Metal Detector

To detect the metal particle in the scrap while loading material on conveyor.

Degassing

Every extruder may be equipped with a vacuum unit, a double-vacuum unit. Through the use of vacuum, loss of viscosity is reduced, and volatile contamination and monomers are extracted.

Intelligent Control

It helps to improve to improve the productivity with minimum man power.