WASHING LINE

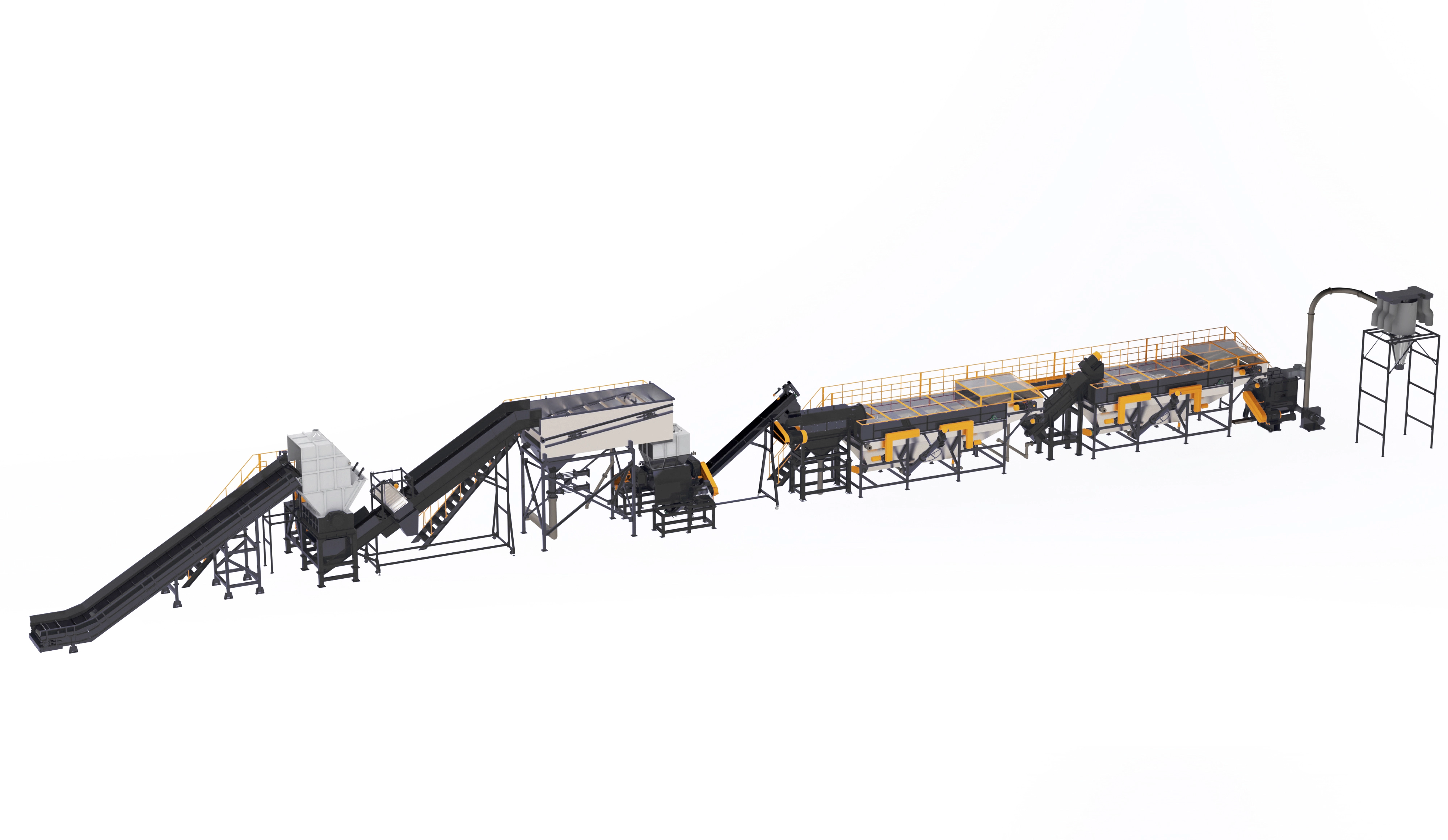

Film washing lines are engineered for handling flexible plastic waste such as LDPE agricultural films, LLDPE stretch films, and PP woven/jumbo bags. Due to the lightweight and tangled nature of films, they require specialized feeding and cleaning components.

The system converts contaminated film into clean, high-quality flakes. The process starts with shredding, followed by hot & cold friction washing and float separation to remove dirt, adhesives, and impurities. For heavily contaminated film, an extra wash cycle ensures maximum purity. The flakes are then processed through a squeezer and thermal/pipeline dryer, delivering moisture-free output.

Rigid plastic washing lines are designed for processing hard plastics like HDPE bottles, PP containers, ABS housings, and PET materials. The process starts with shredding the plastics into flakes, followed by several washing and separation stages.

The pre-washing tank removes sand, stones, and basic dirt. A high-speed friction washer ensures deep cleaning, and for heavily contaminated materials, hot washing with detergent or caustic soda removes oils, adhesives, and labels. The float-sink separation tank sorts plastics by density. Finally, mechanical and thermal systems dewater and dry the flakes, producing clean and nearly dry output.